Advancing and Optimising Engineering from Design to Manufacturing

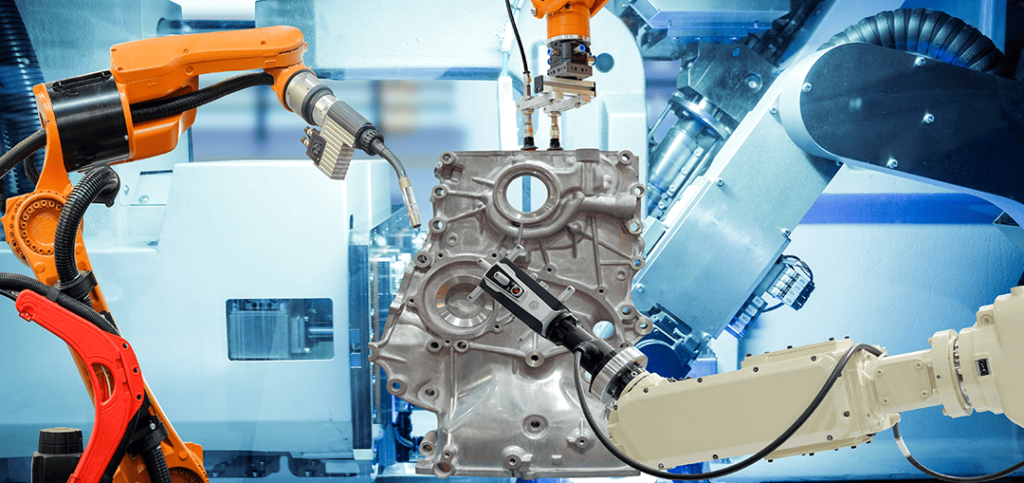

Faced with rising costs and demand for faster delivery, industries are adopting advanced mechanical engineering methods. Integrating cutting-edge technologies accelerates development cycles and boosts ROI. Expertise in design, CAD modelling, simulation, prototyping, and manufacturing supports sectors like automotive, aerospace, medical, and industrial equipment, ensuring precision, quality, and profitability.

Strategic Digital Innovations

Competitive Advantages

Vastly Experienced

We have experience of serving to the leading automotive and industrial OEM’s, designing and developing complex engineering solutions.

End-to-end Capabilities

We offer a wide range of services and solutions, from industrial design and mechanical engineering design services to CAE/CAM, documentation, prototyping, testing, and manufacturing.

Technically skilled and certified SME’s

We have dedicated domain-specific SMEs in Automotive, Medical Devices, Industrial and other industries.

Cost Optimization

Certified Testing Labs and proven product BOM support ensure cost savings.

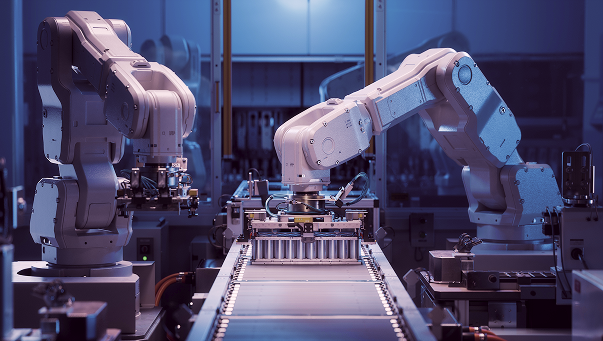

Converging transformation and growth to integrate innovation

Case Study

The future of digital engineering is shaped by cutting-edge trends, including AI-driven solutions, digital twin applications,

The future of digital engineering is shaped by cutting-edge trends, including AI-driven solutions, digital twin applications,